400mm Slitter

600mm Slitter

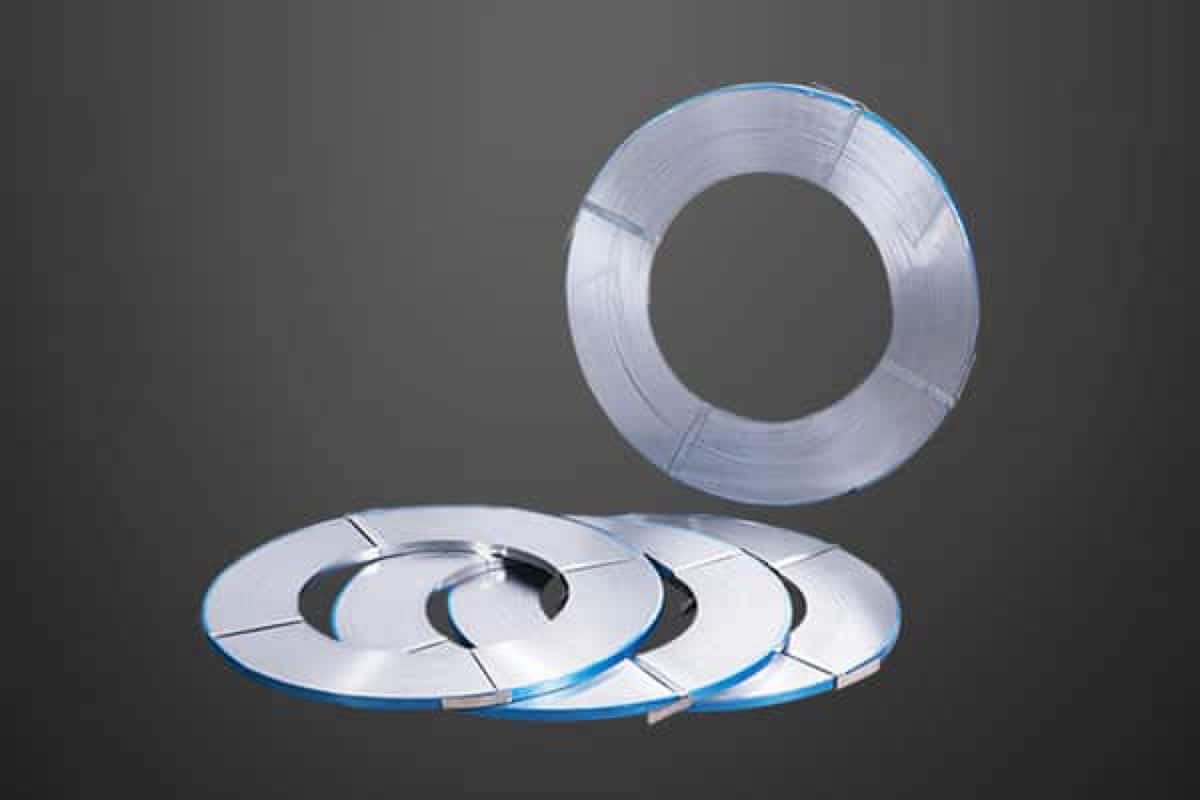

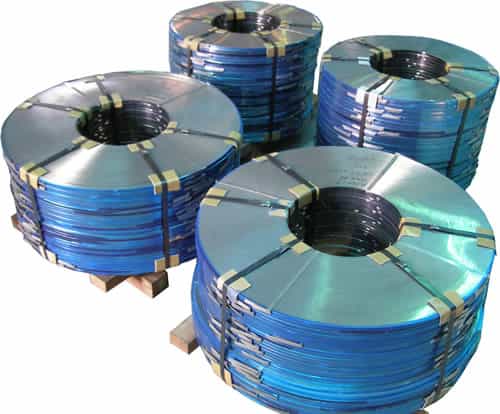

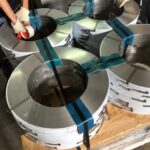

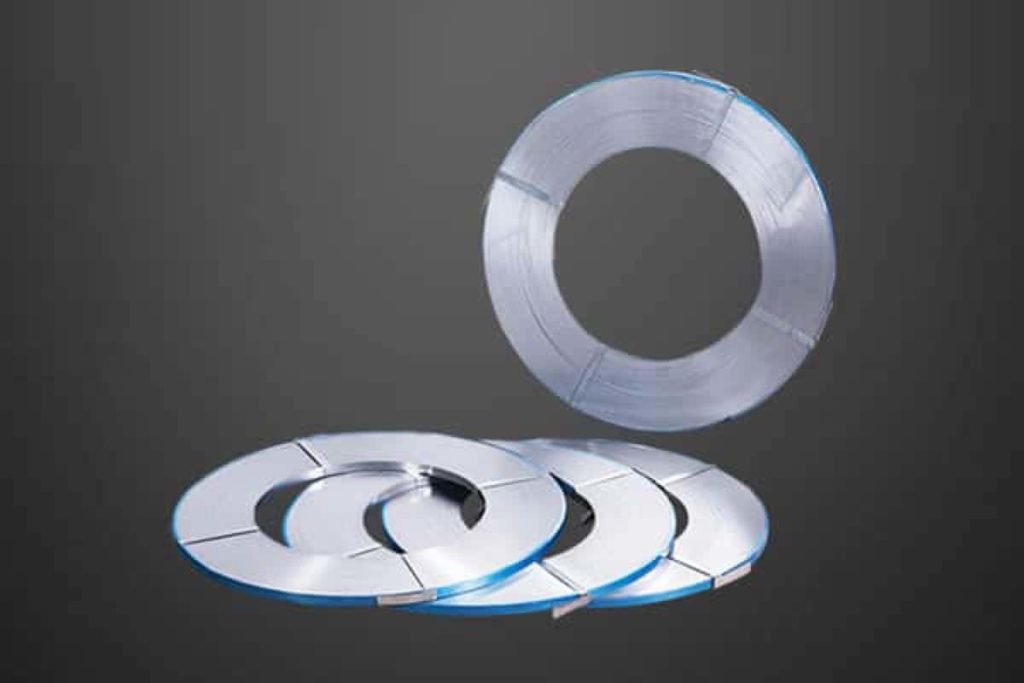

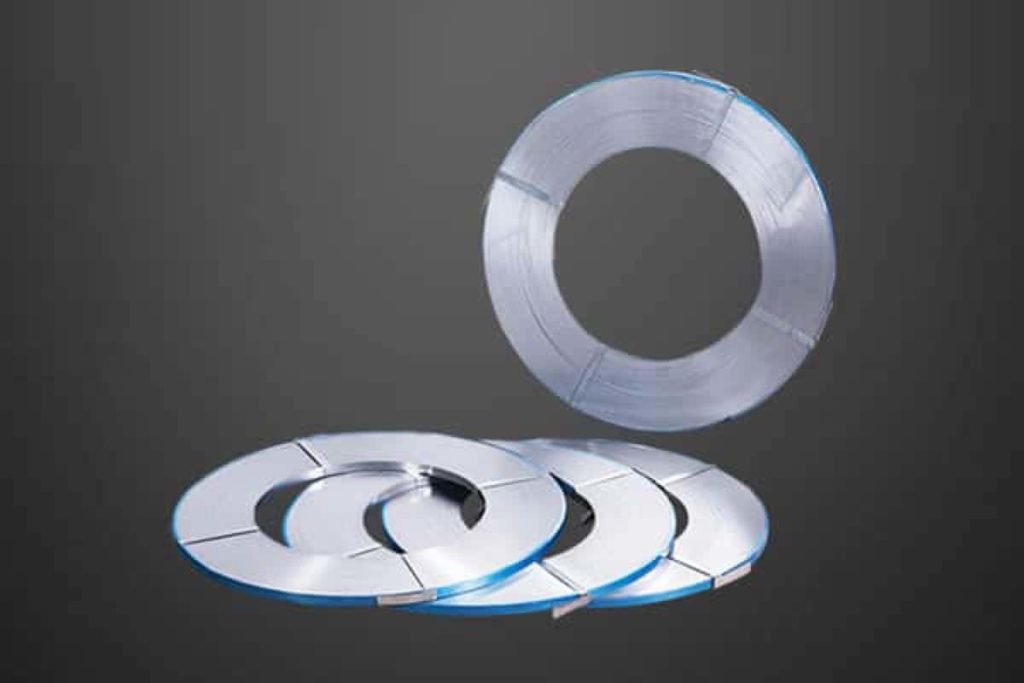

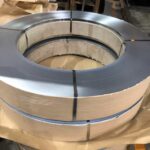

Stainless Steel Strappings/Bandings

Machine Feature:

Applicable to 400mm narrow Stainless Steel Sheets strips, special light weight packing requirements may also be offered upon per discussion.

Thickness: 0.3mm~2.0mm

Width: 7mm~400mm

Film coating: Black & White / Blue colour

Inner Diameter: 200mm/ 300mm/ 500mm

Surface: 2B / BA / HL / No.4

Application: Kitchen Equipment / Home Appliances / White Goods Products / Automotive Parts / narrow, small Diameter pipes, tubes / Electrical Accessories / Medical small parts / Hose Clamps / Door Hinge / Metal Products / Pressing Fabrication and more.

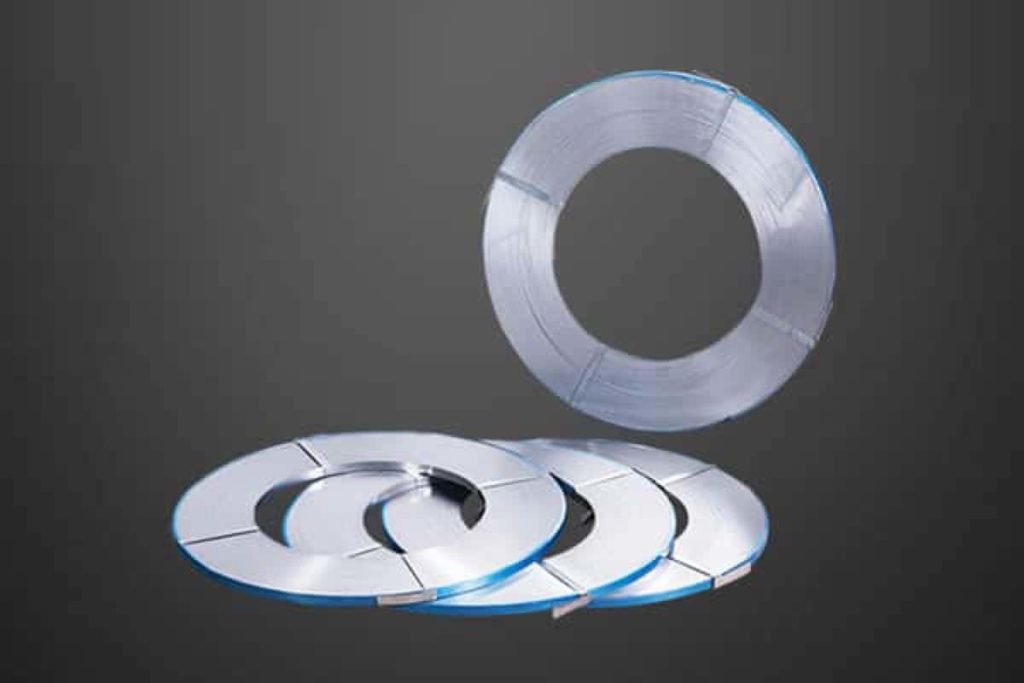

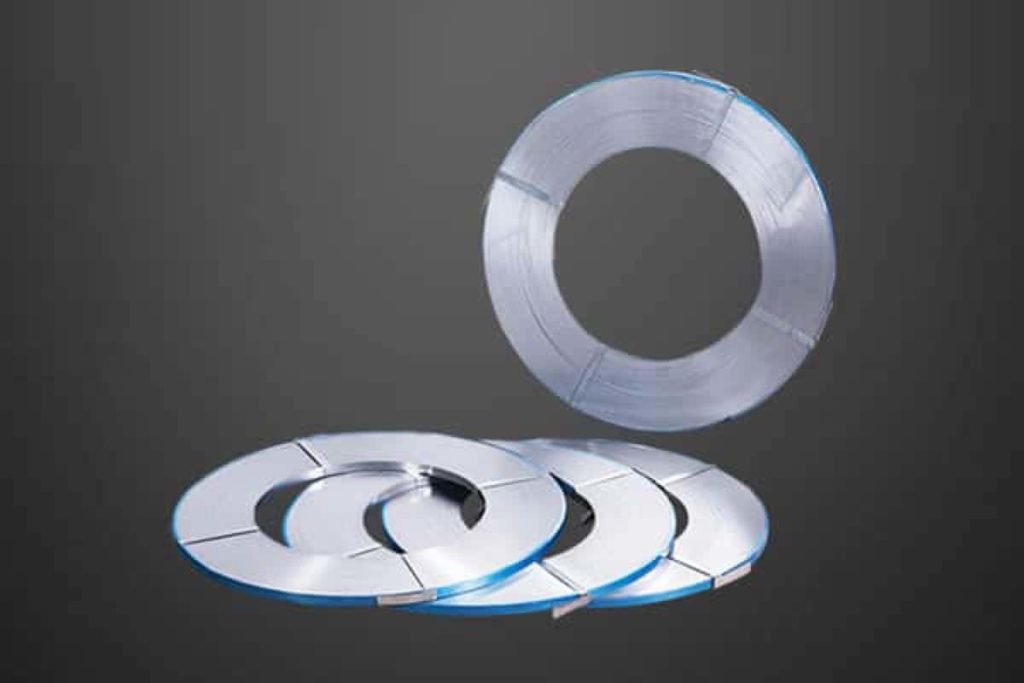

Stainless Steel Strappings/Bandings

Machine Feature:

Applicable to 600mm narrow Stainless Steel Sheets strips, other special width sizes can be allocate wisely.

Thickness: 0.3mm~2.0mm

Width: 13mm~600mm

Film coating: Black & White / Blue colour

Inner Diameter: 200mm/ 300mm/ 500mm

Surface: 2B / BA / HL / No.4

Application : Pipes and Tubes welding / Kitchen Appliances as Stoves, Hoods, Sinks / Commercial Kitchen Construction Equipments and more.

Surface

| Surface | Thickness | Characteristics | Application Guide |

|---|---|---|---|

| 2B | 0.3mm~2.0mm | Finished by heat treatment, acid picked after cold rolling, to processed to make the skin pass line to be white bright. | Medical device, food industry, construction material, kitchen utensils, and Public facility. |

| BA | 0.3mm~2.0mm | Processed with bright heat treatment after cold rolling. The surface finish is bright annealed like a mirrored surface. | Kitchenware, home appliances, construction materials and decorating use. |

| No.4 | 0.3mm~2.0mm | Polishing with No.150-180 abrasives on 2B surface. | Medical device, construction materials and kitchenware. |

| HL | 0.3mm~2.0mm | As known Hair Line, finished by 2B continuous polishing streaks by using abrasive of suitable grain size. | Construction materials, elevator surface, electronic gadgets. |

Chemical Composition (%)

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 304 | ≤0.08 | ≤0.75 | ≤2 | ≤0.045 | ≤0.03 | 8~10 | 18~20 | |

| 304H | ≤0.042 | ≤0.54 | ≤1.12 | ≤0.025 | ≤0.002 | 8~10 | 18~20 | |

| 304L | ≤0.03 | ≤1.00 | ≤2 | ≤0.045 | ≤0.03 | 8~13 | 18~20 | |

| 430 | ≤0.12 | ≤1.00 | ≤1 | ≤0.040 | ≤0.030 | 16~18 | ||

| 316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.045 | ≤0.03 | 10~14 | 16~18 | 2~3 |

| 316L | ≤0.03 | ≤1.00 | ≤2 | ≤0.045 | ≤0.03 | 10~15 | 16~18 |

Mechanical Properties

| Grade | Yield Strength | Tensile Strength | Elongation. | Hardness | |

| N/mm² | N/mm² | % | HRB | HV | |

| 304 | ≥205 | ≥520 | ≥40 | ≤90 | ≤200 |

| 304H | ≤370 | ||||

| 304L | ≥175 | ≥485 | ≥40 | ≤90 | ≤200 |

| 430 | ≥205 | ≥450 | ≥22 | ≤88 | ≤200 |

| 316 | ≥205 | ≥515 | ≥40 | ≤90 | ≤200 |

| 316L | ≥170 | ≥480 | ≥40 | ≤95 | ≤200 |